We are back with the Q&A series dedicated entirely to the discovery of small details about safety which can sometimes go unnoticed.

Have you ever wondered which features set apart a good quality bike chain from a commonly used one? Very often we focus on the thickness and length of the chain, leaving aside other less well known but equally important details.

Let’s find out what they are!

Q1. DIMENSION OF LINKS AND ENDS OF THE CHAIN: how much does the shape matter?

A1. With the same total length and diameter, 2 chains can be made up of several links with smaller internal gaps (the free space between one link and another) or fewer links, which are more elongated. Fewer links results in the use of fewer materials and less processing (e.g. fewer welds) and these chains therefore generally have a lower production cost and retail price. But the savings are associated with less security. In fact, a chain composed of several links, which are close together and with a smaller internal gap, and using the same type of materials and heat/chemical treatments, will offer better resistance to cutting, because it will prevent larger shears from being inserted in the smaller free spaces of the links.

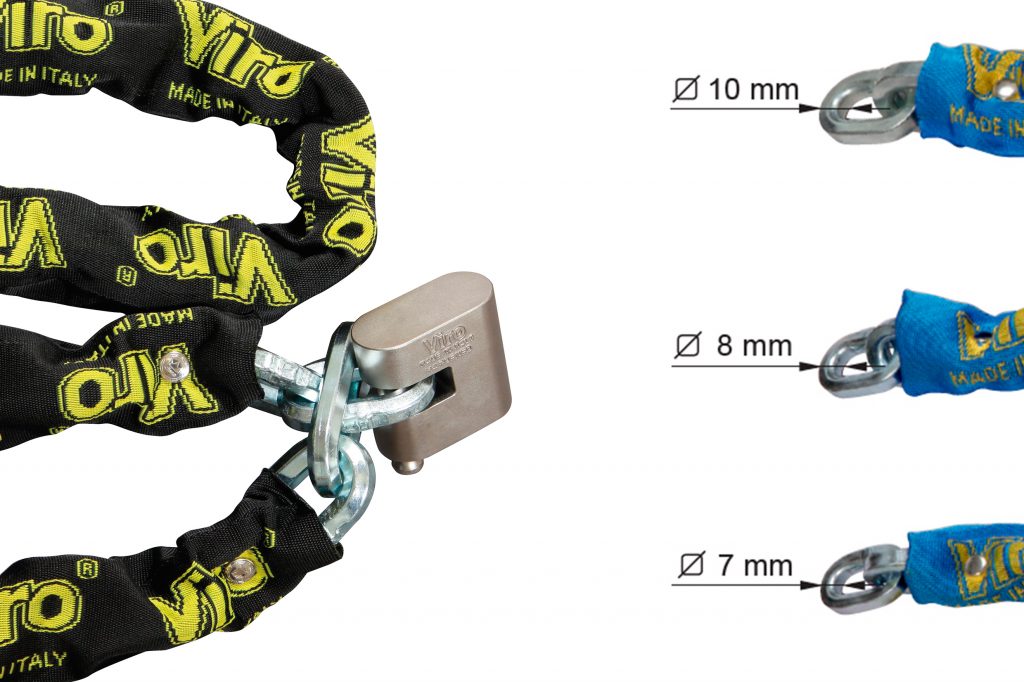

Moreover, with the end (the one that closes the padlock lock-bolt) of the traditional type it will be less difficult for the thief to insert burglary tools such as levers or pincers and break the last link of the chain, especially with a poor quality material, if the link thickness is not sufficient or if the chain has not been case-hardened and tempered. In the looped end (also known as “double loop”), on the other hand, one of the last two links is longer to house the other link inside and close the padlock. The latter type, therefore, allows the padlock lock-bolt to be protected (which is covered and protected by the two links) and does not leave unnecessary free spaces where any burglary tools may be inserted.

Q2. OUTER SHEATH OF THE CHAIN: is it better if made of plastic or synthetic fabric?

A2. It is a common belief that the outer sheath has the sole function of preventing rubbing and damage to the chain and, without doubt, it is one of the main functions, but it is not the only one. If you consider that before you can gain access to the chain you will need to cut the sheath and that the break-in time will therefore be increased, it can be seen that in addition to an aesthetic function the outer sheath also has a protective function. This explains the importance of the choice of materials: whilst a plastic covering, precisely because of the rigidity it gives to the chain, is easily cut, the sheaths made of synthetic material (especially if very flexible and strong, such as nylon fabric) better resist cutting, hindering the action of shears and helping to slow down potential thieves.

This type of covering also gives the chains a flexibility not comparable to those covered with plastic sheaths, allowing them to fold easily on themselves.

Q3. CHAIN LINKS: with round, semi-squared or hexagonal cross-section profile?

A3. This is a parameter which can be easily evaluated by eye, even if its importance is not as intuitive as it is for the dimensions: whilst, in fact, the importance of the thickness of the links is known, it is not so well known that their profile can also be relevant during a burglary attempt. Whilst round cross-section profiles are more easily cut by commercially available shears (which are made to cut round cross-sections), such as those of electro-welded meshes and common chains, semi-squared cross-section profiles (such as the Viro Supermorso with chain) or hexagonal profiles (such as the Viro Eurothor with chain) are more difficult to attack.

It is therefore important to check, before purchasing, not only the length and thickness of the chain, but also the profile of the links, the material of the outer covering and the end of the chain.

Read also:

>> Q&A: 4 facts about padlocks that (maybe) you didn’t know!