Shackle, rod, combination, one-piece or chain padlocks: there are various types of padlocks on the market with various functions, ranging from the protection of a simple locker or a bike, to the protection of containers or shutters.

So what features does a padlock have to have to prevent a thief from opening it?

To give a correct answer it is essential to know the techniques used by thieves to open or force the padlocks and the tools they use.

Today, we will see one of the most common techniques, that is, the cutting of the shackle or rod with shears or cutters, so we’re going to find out what features a padlock must have to prevent the thief from being successful.

Although the lock is also a particularly sensitive point for this type of burglary (if the cylinder is weak), it is the shackle/rod which represents the real Achilles heel of the padlock.

As can be seen in the above video, it is, in fact, the shackle which is cut and allows the opening of the padlock.

Features of the anti-cutting padlock

The indispensable features in a strong shackle (or rod) include:

1. Dimensions and “clearance”

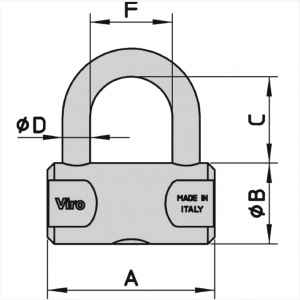

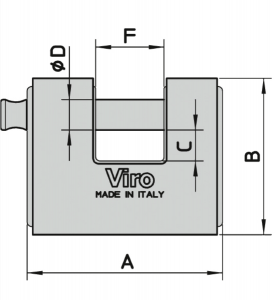

It is clear that the more free space there is between the shackle and the body of the padlock the easier it will be to insert tools such as shears or cutters to cut the shackle. This is why padlocks with long shackles are only recommended when the two fixing points are far apart and do not allow the use of other types of padlock. Before purchasing the padlock you should therefore check the dimensions of the “shackle clearance” (i.e. the empty space under the shackle, in the case of shackle padlocks) or the width of the eyelets (in the case of rod padlocks), evaluating, based on the specific characteristics of the fixing points, the padlock which best suits it.

F x C

F x C

2. Thickness

When buying a padlock, in order to avoid a possible attempt to cut, it is always a good idea to check that the thickness of the shackle /rod is sufficient to provide adequate resistance to cutting. In fact, each padlock has different and specific features for the function it will cover. However, a good thickness, depending on whether it is an shackle or a rod, ranges from 8 to 13 mm in diameter. These are, of course, indicative measurements, to which must be added all the other characteristics which contribute to making the padlock more resistant.

3. Construction material and treatments

With regards to the shackle, which is the part most exposed to attacks, the best material is steel which has been correctly hardened and case-hardened. In fact, the hardening increases the mechanical strength, and consists in heating the metal to high temperatures and then cooling it rapidly. The case-hardening of the surface, that is, its carbon enrichment, improves, on the other hand, the resistance to cutting.

Increase the security of the shackle of a padlock:

- Decreasing space between shackle and body

Cutters are all the more effective the longer their arms are, but in order to exert the leverage effect, the blades must open wide enough to surround the shackle or rod to be cut.

When it is really impossible to use padlocks with a shackle or rod of an ideal size with respect to the fixing point, we suggest, before closing the padlock, to insert washers or steel bolts (possibly hardened) with an internal diameter just greater than that of the shackle or rod, all around the locking point, so as to reduce the empty space as much as possible. Here’s a good example:

- Increasing corrosion resistance

As we saw in the video, the more oxidized and corroded padlocks are more vulnerable and easier to cut. For this reason the resistance of a padlock to break-in attempts is as important as the potential lifetime of the product. Therefore, in addition to the hardening and case-hardening, the resistance to oxidation is achieved by copper plating, which serves to bond on the surface the subsequent steps of nickel and chrome plating, which increase the resistance to corrosion.

Discover the range of Viro padlocks at the dedicated page!

Dear sir,

I am a reseller from Malaysia. I’m currently sourcing the anti-cutting padlock for my customer and I am interested to propose the product below to them.

Viro Anti-cutting Padlocks

Qty : 5 units

I would appreciate it if you could advise me of the followings :

a).the reseller price

b) the suggested retail price

c) the delivery lead time

d) warranty

e) shipping & handling

Destination :

Town : Puchong

State : Selangor

Zip code : 47100

Country : Malaysia

Do you have a rep or an agent in Malaysia ?

Thanking you in anticipation.

Best regards.