In today’s post we will see how much the shine of the locks and the treatments they undergo affect security.

> The shinier it is, the better it is made. Is that correct?

Again, it depends.

Whilst it’s true that a smooth, shiny surface with a “mirror-like” chrome platingof a steel armour, such as that of the Viro Panzer, generally derives from precise and constant machining of materials, it may be the case that some products imported from the Far East undergo a transparent surface painting to make the brass or other materials more polished. Obviously this last “treatment” is purely aesthetic and is therefore not an indication of a well-made internal mechanism.

In a test carried out on two rectangular padlocks, in fact, whilst the Made in Italy product, after 18 hours in salt spray, saw the external colouring of the brass become darker, it was found to be fully operational; on the other hand, whilst the importedproduct(treated with shiny transparent paint) looked little different than before, it had an internal mechanism blockage which prevented normal opening/closing of the padlock.

Fully oxidized internal mechanism of the import padlock

Shackle of the imported padlock oxidized and no longer functional

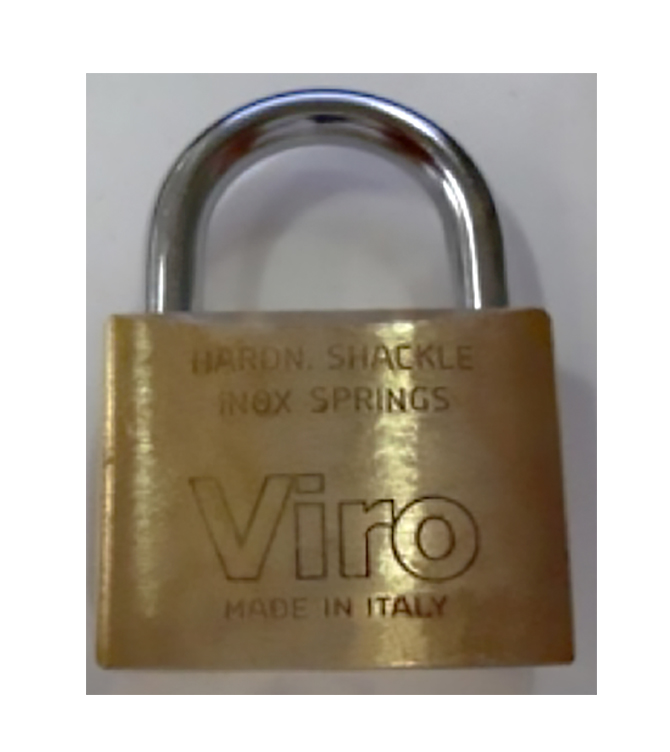

Viro padlock working after being cleaned

Sometimes, on the other hand, matt satin effect finishes are used to “mask” small surface imperfections of the machining or of the materials themselves.

The matt satin chrome effect, therefore, does not necessarily imply lower quality, provided that the materials used have the right properties and the mechanism is perfectly designed and operational, but it can simply indicate slightly more porous external surfaces.

> Resistance to cutting of the shackle/rod: what are the essential treatments?

As we explained in this article, there are several characteristics which a padlock should have in order to be able to cope in the best way with possible cutting attempts.

Let’s just mention one: the best material with which a shackle can be made, which is the part most exposed to attack, is properly hardened and case-hardened steel. The hardening, which consists of bringing the metal to high temperatures and then cooling it rapidly, increases the mechanical strength of the shackle or rod of a padlock, while its case-hardening, that is, carbon enrichment, exponentially improves the shear strength.

Here are the other key characteristics to avoid this kind of attack!

Also discover 4 curious facts about padlocks! Did you know them?