There are locks of all types, shapes, sizes and prices. How does one differentiate a good quality product from a poor one?

Apart from the trust we place in the manufacturer and retailer, there are some important features which can be checked.

Materials

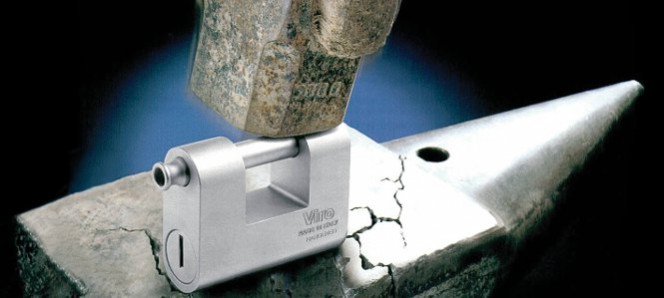

The shackle (or rod) is the most exposed part of the lock and the part most frequently subject to attacks. For this reason it must be manufactured from materials which provide the greatest possible resistance to cutting, pulling and blows.

Unfortunately, the materials most resistant to tensile forces usually have a poor resistance to cutting, whilst those very resistant to cutting are fragile if subjected to impacts. The material with which shackles and rods are manufactured must therefore be properly treated in order to achieve the best possible resistance to the various types of attack which the lock might undergo.

The best material for this type of use is properly hardened and case-hardened steel. The hardening, which consists in heating the metal to high temperatures and then cooling it rapidly, gives it the mechanical strength, while case-hardening the surface, that is, its carbon enrichment, improves the resistance to cutting.

Manufacturers who use hardened steels to manufacture shackles and rods of locks generally mark them as “hardened”, but, unfortunately, the mere presence of this marking is not in itself sufficient to guarantee that the hardening was carried out correctly: high tech facilities are needed together with a high level of skills in their use to obtain the desired results. Many low cost imported products are manufactured in production facilities (typically located in the Far East) which lack both the systems and skills to maintain uniform thermal treatment, thus adversely affecting the quality of the end result.

As well as withstanding burglary attempts, the durability and a high resistance to oxidation and corrosion is also important, which is provided by chemical treatment, by means of copper, nickel and chrome plating.

A good quality lock lasts a long time, even if used outdoors and its steel parts do not corrode in just a few months; thanks to a correct nickel and chrome plating they will last several years.

Body shape and size

Many of the attempts to break locks by brute as well as those in which attempts are made to pick the locks are facilitated by the square shapes of the body. A square shaped body offer greater possibilities for gripping the lock with burglary tools, it can easily placed in a vice or held firm whilst using cutting or drilling tools, and it allows it to be held firmly whilst working with lock picks. For this reason, the best quality locks have rounded shapes and rounded corners. The lack of sharp edges also has the advantage of avoiding abrasions to the hands when they are being used.

2 latches

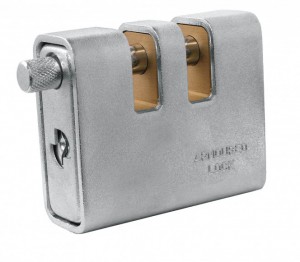

A good quality padlock blocks the shackle (in the case of shackle type padlocks) or the closing rod/pin (in the case of padlocks for chains or shutters) at 2 points, to guarantee a better resistance to pulling.

A single latch is particularly vulnerable because it can be triggered directly, without acting on the lock, simply by introducing a wire into the plug, especially if it does not have rear protection (just the tooth of a fork would be sufficient) and then directly moving the latch spring.

The presence of the 2 latches can be easily checked because there will be 2 recesses on the shackle or pin instead of one.

Plug with rear protection

Good quality locks also have a protection which closes the rear of the plug (the rotor in which the key is inserted), so as to prevent direct access to the opening mechanism using a wire.

This protection is not present in poor quality locks and by inserting a thin lever (even just the tooth of a fork) into the plug it is possible to reach and directly trip the latch without even forcing the lock.

Cut-resistant rotary rod

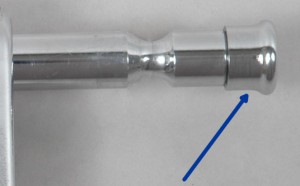

In padlocks closed by one or more rods, rather than by a shackle, such as padlocks for chains and shutters, it is essential that the rods rotate, in order to counteract the action of cutting tools such as saws and grinders. If an attempt is made to cut them, the rotating rods rotate together with the blade, preventing it from gripping and cutting.

The rotating rod can be rendered ineffective if it possible to block it with pliers or a vice during cutting, so it is essential that the rod is not left uncovered, and it must be almost entirely protected from the fixing points in which it is inserted. The lock must therefore always be chosen in relation to its fixing points, so that they couple in the most precise way possible. In padlocks where the head protrudes from the body it is important that this has a programmed breakage point, so that if an attempt is made to cut the rod whilst holding it still by the head this will break under the stress.

Programmed breakage rod grip

The best padlocks for shutters and chains have a programmed breakage rod grip. This means that if an attempt is made to pull off the rod by grasping the grip with burglary tools, this gives way at a point predetermined by the manufacturer, leaving the rod in the closed position.

The alternative to prevent pulling off the rod is to ensure that it cannot be gripped, with the closed padlock being fully housed in the body. In this case, the opening is carried out by means of a spring which, by turning the key, pushes the rod outside. However, the opening may become problematic if the eyes in which the rod is inserted tend to hold it in place. It can easily happen in a shutter, for example, that the eye fixed to the ground and the one fixed to the shutter become misaligned, thus tightening the rod and preventing the opening spring from pushing it outside.

Absence of clearance

A well-manufactured padlock is a small precision machine, which does not have any significant clearance between its moving parts: between shackle and body, between body and plug and especially between pins and key. The presence of significant clearance is, on the contrary, an indication of poor machining which renders the padlock vulnerable both to brute force attacks and lock picking. A shackle that is not tightly secured is more easily ripped off and a lock machined with large tolerances simplifies the opening with a pick by manual alignment of the pins (lock picking).

The lock

As in all closing systems, the actual lock is one of the fundamental elements for security and reliability also in the case of padlocks.

The number of pins

The number of pins and the shape of the counterpins are important to counteract opening by lock picking. To open a lock with a pick it is necessary to align all the pins in the open position using this tool, and the difficulty in doing this increases with the number of pins. To align the pins in the right position using the pick it is necessary to touch them and move them with the tool in order to find the opening position. The shape of the counterpins can be designed in order to make this operation more difficult. “I-shaped profiles” or “mushroom profiles” ensure that the counterpins tend to get stuck in their seats under the action of the pick, making the movement difficult.

Key profile

The shape of the part of the key which is inserted in the lock is called its profile. The more elaborate the profile, the greater its security, because it is more difficult to insert burglary tools in complex profiles. The most common profile, called “Paracentric” or “Universal”, has the classic rounded “S” shape, which leaves large enough spaces for the introduction of burglary tools.

More complex profiles are, on the other hand, characterised by various acute angles or straight lines combined with each other, which make it much more difficult to introduce picks and other tools.

Of course, in order to achieve complex profiles a greater precision is required in the machining and a consequent reduction in the clearances, compared with the Universal profile; for this reason, poor quality products, such as many of those coming from the far East, do not use elaborate profiles.

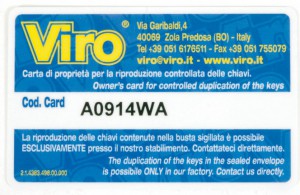

In addition, the more controls there are in the copying of the key, the more difficult it is to make illegal copies. There are padlocks with patented profile keys and also keys having profiles with registered shapes. In these cases, the copies can be made only at Authorized Centres. There are also versions for which copies are only available by contacting the manufacturer.

This type of lock is almost always accompanied by a coded ownership card declaring that copies of the keys may be made.

In addition to this ownership card, it is in some cases also necessary to present an identity document of the person requesting the copy in order to increase even further the level of security.

Key systems

When using several locks simultaneously, for example to close the various shutters of a shop, or when one simply wishes to use the same key to open various padlocks, or padlocks and locks, it is important to check that the chosen model allows a keyed alike system (KA) or master key system (MK) to be set up.

In a Master Key system (MK) the master key opens various locks, each of which can be opened with its own key (KD).

Good quality padlocks are manufactured in such a way as to also allow, upon request, the creation of hierarchical systems (different levels of keys, each able to open one or more groups of different padlocks) which guarantee access rights according to the predetermined programme and, at the same time, minimising the number of keys in use.

Anti-drill plate

The lock of a padlock may be attached by drilling the plug, to bring the pins out and then rotate it. For this reason, the best quality padlocks have lock protected by a drill-resistant plate. The plate can be fixed, so as to provide protection by its own mechanical strength, or rotary.

In this case, in addition to the strength of the materials, the protection derives from the fact that if one attempts to drill the lock with a drill bit this actually grips the plate, which begins to rotate simultaneously with the drill bit itself and prevents it from advancing.

Watch the video of the tests the Viro padlocks undergo