Some people call them “snakes”, or merely “cables”. They consist of a series of cylinders through which a steel cable passes, so this is why their technical name is “armoured twisted cables” For several years they have been one of the most popular solutions for locking up bicycles and scooters, even large powered ones. At first glance they seem very strong, but is that really the case?

How they are made

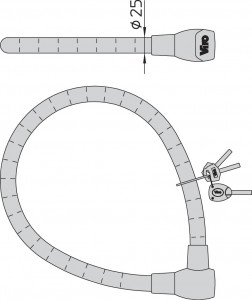

This particular type of “chain” has a twisted cable on the inside protected on the outside by an armour, formed by steel cylinders. The locking mechanism is obviously fixed to the two ends.

Advantages

As is the case for armoured padlocks the aim of the armour is to achieve a good compromise between security and ease of use. In particular, by means of the cylinders which make up the armour, one is able to achieve an outside diameter which is much larger than a simple twisted cable or chain, making this solution much harder to attack with cutters and shears, in which the opening of the cutting blades are not normally suitable to grip objects with diameters greater than 20 mm.

The main advantage of the armoured cable is that by having such a large outside diameter it won’t be attacked by cutters and shears.

At the same time, since the cylinders are hollow inside, the overall weight can be limited and, since they are coupled together in such a way that they can be moved relative to each other, it is possible to maintain a fair degree of flexibility, although not at the level of an unarmoured twisted cable or a chain.

Just like normal cables and chains, armoured twisted cables also have the advantage, if they are long enough, of allowing various parts of the two-wheeled vehicle to be locked up together (typically, wheels and frame) and to a fixed point.

If the armoured twisted cables are quite long they allow the bicycle or scooted to be locked up in the best possible way, by fixing the wheels and frame together and to a fixed point.

Limitations

From the point of view of practicality, a limitation of the armoured twisted cables is that, no matter how flexible they are, they are still stiffer than a chain, and for this reason they can be awkward to store and use in situations in which there is limited space and greater adaptability is needed.

From the point of view of security, on the other hand, their potential weakness is the strength of the cylinders of the armour. It is true that the cylinders cannot be directly attacked with shears, but if one can easily flatten or deform them one can expose the twisted cable inside which, having a much smaller diameter, can be easily cut with simple wire cutters.

The real weakness of armoured twisted cable is the possibility, in the case of cheap products, to deform the cylinders of the armour and expose the inner cable which can be easily cut.

The difference consists in the quality of the materials. The armour in the cheap products is often made of poor quality materials with a small thickness, which can be squashed with a simple hammer or deformed with a common screwdriver or other type of lever. Another critical point of poor quality products is the locks: they are generally weak, with imprecise machining and very simple mechanisms. The result is that they yield if they are pulled and they open easily even without any particular skill.

Conclusions

Considering a same level of quality, armoured twisted cables are without doubt a more secure solution than simple twisted cables, but they are decidedly less easy to use and secure than a padlock and chain. Beyond the theoretical considerations, however, the difference consists, as always, in the real quality of the product. If the armour and the lock are manufactured well, it is actually possible to achieve a good compromise between strength, weight and cost. On the contrary, where materials and machining leave something to be desired, there is only an apparent strength, given by generous outside dimensions, which hide a real vulnerability.

See the technical characteristics of the Viro Serpis and Serpis Plus armoured twisted cables